Separating mixtures into their constituent parts is a crucial step in many industries and scientific studies. The Sieving method is one such popular separation technique. This article will examine the sieve method, including its foundation, uses, benefits, and more.

Introduction to the Sieving Method of Separation

The sieving method is a physical separation method that is frequently used in a variety of sectors, including mining, food processing, medicines, and environmental studies. This technique provides a flexible approach to many applications by effectively separating solid particles according to their particle size.

The sieving procedure is essential for assuring product quality and uniformity in sectors like pharmaceuticals. To separate particles of various sizes and ensure that the finished goods fulfil the required criteria and standards, pharmaceutical makers use sieving. Sieving aids in the elimination of contaminants and the achievement of homogeneity in pharmaceutical formulations by successfully separating bigger particles from smaller ones.

Sieving is used in the food processing sector for a variety of tasks. It makes it possible to separate particles of various sizes, guaranteeing the correct consistency and texture of food items. For instance, sieving aids in the creation of smooth, fine powder when producing powdered substances like wheat or spices. In order to ensure that food items have the ideal particle size distribution for flavour, texture, and appearance, sieving is also used for quality control.

history of the Sieving Method

The sieve process has been used for thousands of years, having its origins in ancient cultures. Throughout history, the notion of utilising sieves to separate particles based on size has been a key method in many civilizations and businesses.

Sieving dates back to ancient Egypt, when sieves constructed of wood, reeds, or woven cloth were used to separate grain and flour. For food production and storage, the Egyptians recognised the need of eliminating contaminants and ensuring uniform particle size.

Sieves were also widely used for a variety of reasons in ancient China. The Chinese developed advanced methods for producing silk, separating silkworm cocoons to get fine silk fibres using sieves made of fine bamboo or silk threads. For silk textiles to have the necessary quality and texture, sieving was essential.

In Europe, the usage of sieves increased during the Middle Ages in sectors including mining and metallurgy. Based on their particle size, minerals and ores were separated using sieves consisting of woven wire mesh. In order to extract rich metals and minerals from raw materials, this technique was essential.

What is the Sieving Method?

Definition and Purpose of Sieving

Sieving is the technique of separating particles depending on their size by passing a mixture through a sieve or mesh with uniform-sized pores. Sieving is used to separate particular fractions or to eliminate impurities or pollutants from a mixture.

Principle of Sieving

The sieving method works on the idea that particles smaller than the mesh holes of a sieve pass through while particles bigger than the apertures are trapped. This separation arises owing to particle size and shape differences.

Equipment Used for Sieving

Sieves, a sieve shaker, and a collecting pan are the main pieces of equipment used in the sieving procedure. Sieves are generally composed of metal or plastic and come in a variety of mesh sizes. A sieve shaker causes mechanical vibrations in the sieves, which aids in separation.

How Does the Sieving Method Work?

The sieving method separates solid particles in a mixture based on particle size using a succession of sieves with varying opening sizes. To accomplish efficient and precise separation, this method entails multiple phases.

- Sieve Selection: The first step is to choose the suitable sieves with various mesh sizes. The mesh size is the number of apertures per inch or the size of the sieve’s openings. Larger opening sieves are utilised at the top, while smaller opening sieves are used at the bottom.

- Sample Preparation: To achieve reliable findings, the sample to be sieved is carefully prepared. Breaking down any agglomerates, homogenising the sample, and eliminating any foreign materials or impurities may be required.

- Sieving Process: The prepared sample is placed on the top sieve with the biggest apertures for sieving. The sieves are then layered on top of one another, with the biggest mesh size on top and the lowest at the bottom. The sieve stack is firmly fastened together to keep them in place.

- Sieve Shaker: A sieve shaker is used to aid in the separation process. The sieve shaker vibrates or oscillates the sieves, causing particles to move and pass through the apertures or to be kept on the sieve surface. To optimise the separation process, the strength and duration of the vibrations may be modified.

- Separation and Collection: As the sieve shaker vibrates, the particles smaller than the openings in each sieve pass through and collect on the sieve below, while particles larger than the openings are retained on their respective sieves. This separation continues as the sample progresses down the stack of sieves.

- Analysis of Sieve Results: Once the sieving process is complete, the collected fractions on each sieve are carefully examined and analyzed. The amount of material retained on each sieve is measured or weighed. This data provides valuable information about the particle size distribution in the sample, such as the percentage of particles within specific size ranges.

Researchers and analysts can ascertain the distribution of particle sizes in the mixture, which is essential for a variety of applications, by analysing the fractions that have been collected. The identification of various particle size fractions and the evaluation of their relevance in the mixture are made possible by the sieving method’s exact and controlled separation.

In general, mechanical vibrations, the use of sieves with different mesh sizes, and careful examination of the separated fractions are how the sieving process operates. This method is essential in fields like pharmaceuticals, food processing, mining, and environmental studies since it allows the separation of solid particles according to their size.

Applications of the Sieving Method

The sieving method finds extensive applications in various industries and laboratory settings:

Industrial Applications

In industries such as mining, construction, and pharmaceuticals, the sieving method is used for quality control, grading materials, and ensuring consistent particle size distribution in products.

Laboratory Applications

In scientific laboratories, the sieving method is utilized for particle size analysis, soil analysis, environmental analysis, and research purposes. It helps in studying the characteristics of different materials and their suitability for specific applications.

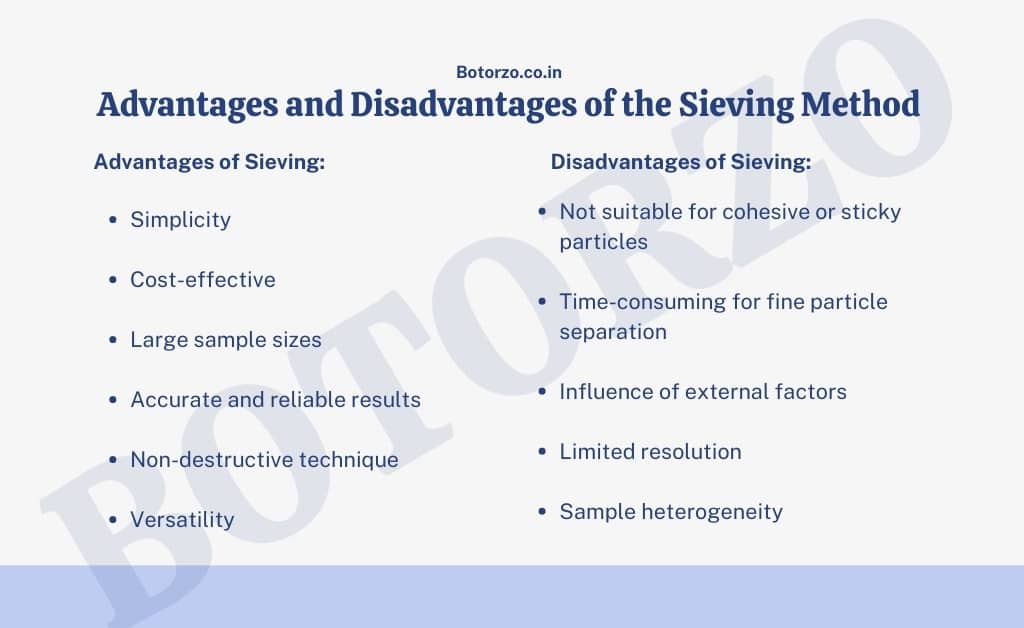

Advantages and Disadvantages of the Sieving Method

The sieving method offers several advantages and disadvantages, which are important to consider when utilizing this technique for particle size analysis and separation. Understanding these pros and cons helps in making informed decisions and optimizing the sieving process for specific applications.

Advantages of Sieving:

- Simplicity

- Cost-effective

- Large sample sizes

- Accurate and reliable results

- Non-destructive technique

- Versatility

Simplicity: Sieving is a straightforward and easy-to-understand method, making it accessible to a wide range of users. It does not require complex equipment or specialized training, allowing for convenient implementation.

Cost-effective: The equipment required for sievings, such as sieves and sieve shakers, is relatively affordable compared to other particle separation techniques. This makes sieving a cost-effective option for many industries and research laboratories.

Large sample sizes: Sieving can handle relatively large sample sizes, allowing for representative analysis and reliable results. This is particularly advantageous in industries where bulk material analysis is required.

Accurate and reliable results: When performed correctly, sieving provides accurate and reliable data regarding the particle size distribution of a sample. This information is crucial for quality control, process optimization, and research purposes.

Non-destructive technique: Sieving is a non-destructive method, meaning that the sample remains intact after the separation process. This allows for further analysis or retesting if necessary.

Versatility: The sieving method can separate a wide range of particle sizes, from large aggregates to fine powders. This versatility makes it suitable for various applications across different industries.

Disadvantages of Sieving:

- Not suitable for cohesive or sticky particles

- Time-consuming for fine particle separation

- Influence of external factors

- Limited resolution

- Sample heterogeneity

Not suitable for cohesive or sticky particles: Sieving is not effective for separating particles that are cohesive or sticky in nature. These particles tend to adhere to the sieve surfaces, leading to inaccurate results or clogging of the openings.

Time-consuming for fine particle separation: Sieving fine particles can be time-consuming due to the slow passage of particles through the sieve openings. The process may require longer sieving times or the use of specialized techniques to enhance separation efficiency.

Influence of external factors: The accuracy and reliability of sieving results can be influenced by various external factors. Vibration intensity, sample preparation techniques, particle shape, and characteristics of the sieves can impact the final outcomes.

Limited resolution: Sieving provides discrete size fractions based on the available sieve sizes. The resolution or granularity of the particle size data is limited to the mesh sizes of the sieves used. Obtaining highly detailed or continuous size distribution data may require additional techniques or analysis.

Sample heterogeneity: In some cases, the particle size distribution within a sample may not be homogenous. Variations in particle shape or density can affect the accuracy of sieving results, leading to potential errors or bias.

By considering these advantages and disadvantages, users can optimize the sieving process, address potential limitations, and obtain meaningful and reliable particle size data for their specific applications.

Sieving Method vs. Other Separation Techniques

While the sieving method is widely used, it is essential to understand its advantages and differences compared to other separation techniques:

Sieving vs. Filtration

Unlike filtration, which separates particles based on their ability to pass through a porous medium, sieving relies on particle size and shape for separation.

Sieving vs. Sedimentation

Sedimentation involves allowing particles to settle under the influence of gravity. It is primarily used for separating solid particles from liquids based on their density, while sieving focuses on size-based separation.

Sieving vs. Centrifugation

Centrifugation uses centrifugal force to separate particles based on their density and size. It is more effective for separating fine particles and has a higher processing capacity compared to sieving.

Conclusion

The sieving method of separation is a valuable technique that allows the separation of mixtures based on particle size. With its wide range of applications, simplicity, and reliability, it plays a crucial role in industries and laboratories. By following proper procedures and considering the advantages and limitations, accurate and meaningful results can be obtained through the sieving method.

FAQs

What materials can be separated using the sieving method?

The sieving method can be used to separate a variety of materials, including sands, powders, granules, and solid mixtures.

Is the sieving method suitable for both large and small particle sizes?

Yes, the sieving method can effectively handle a wide range of particle sizes, from large aggregates to fine pow

How can I improve the accuracy of sieving results?

To enhance the accuracy of sieving results, ensure proper sample preparation, use high-quality sieves, optimize vibration intensity, and carefully analyze the collected fractions.

Can sieving be automated?

Yes, sieving can be automated using advanced equipment such as automatic sieve shakers. These devices provide consistent vibrations and offer features like programmable settings for efficient and reliable sieving.

Are there any safety considerations when performing sieving?

When performing sieving, it is essential to follow safety guidelines. Wear appropriate personal protective equipment (PPE), such as gloves and goggles, to protect against potential hazards associated with handling materials and operating the equipment.

Our Another Domains Vidyapedia.in